Applications

The primary applications of Structural Health Monitoring are detection and localization of defects in the investigated component. The measurement data collected by the SHM network are initially available as pure A-scans. Considering the associated actuator and sensor positions, imaging results can be calculated from the measurement data, which are comparable to C-scans of conventional ultrasonic inspections.

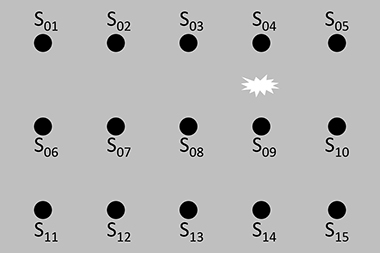

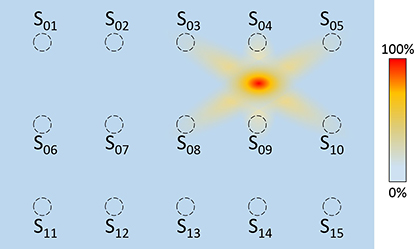

Figure 1 shows a sensor network with sensors S01 to S15 applied to a plate (gray area). Between the sensors S04 and S09 a defect is inserted as a white recess. Due to the defect, the wave propagation in the signal paths S04 → S09, S03 → S10 and S05 → S08 is most strongly influenced. If the A-scans of all measurement paths are compared with each other before and after the damage occurs, for example via a correlation function, a probability distribution of an existing damage can be calculated for the area of the sensor network (see Figure 2).

Fig. 1: Sketch of a component with a SHM sensor network and a damage between S04 and S09.

Fig. 2: Sketch of the component results generated from the sensor data according to Fig. 1 with color scale for defect probability distribution.