Facilities for Plate Inspection

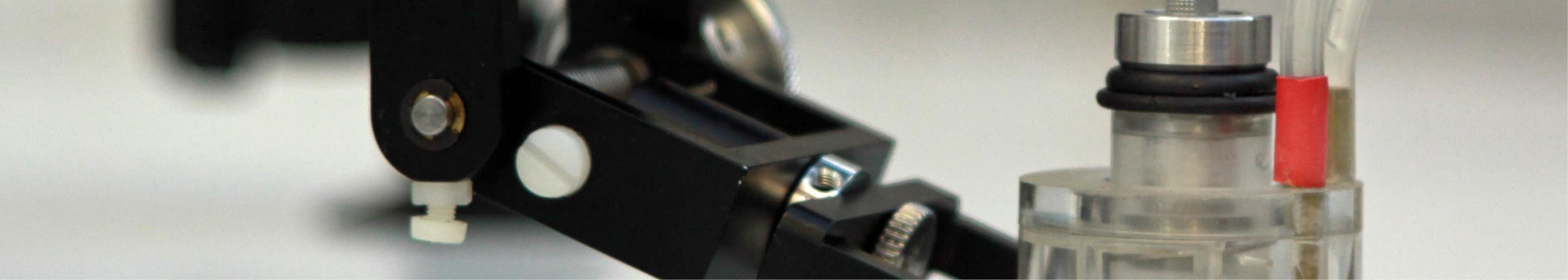

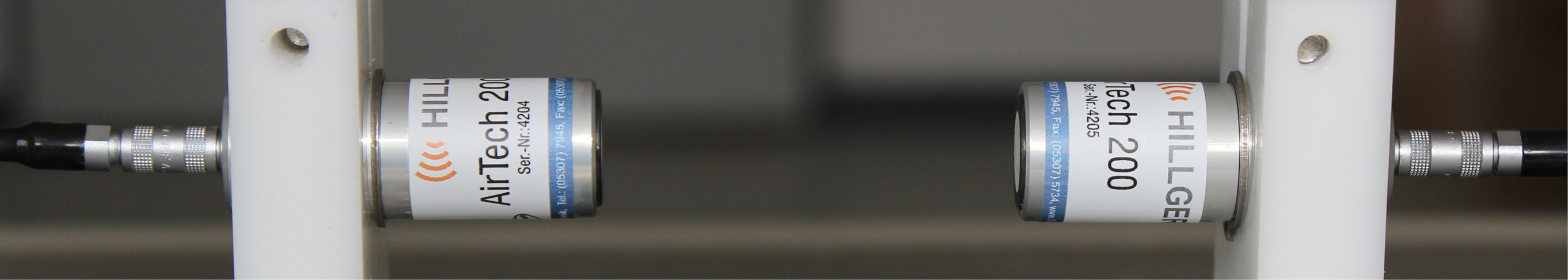

The FlatScan is a robust scanner for air-coupled investigations of flat components with a thickness of up to 90 mm in through-transmission technique and pitch-catch technique in laboratory and industrial applications. It consists of two synchronously moving vertical scan axes on the opposite sides of the component and one axis in the horizontal direction. The mechanical resolution of all axes is 0.15 mm. The maximum scanning speed is 400 mm / s. Systems with scan areas of up to 3 x 2 m are available.

FlatScan 1000

The FlatScan 1000 offers a scanning area of around 1000 x 1000 mm. The technical data are listed in the table below.

| Power input | 700W (230V AC, 3 A) |

| Footprint x High | 730 x 1760 x 1640 mm |

| max. scanning area | 105 kg |

| Resolution of scanning axis | 0,15 mm (scanning and index axis) |

| Max. speed of scan axis | 400 mm/s |

| Max. speed of index axis | 125 mm/S |

| Max. mass of test body | 50 kg |

Tab 1: Technical data of the FlatScan 1000 mechanics

FlatScan 2500

The FlatScan 2500 offers a scanning area of around 2500 x 2500 mm. The technical data are listed in the table below.

| Power input | 700W (230V AC, 3 A) |

| Footprint x Hight | Scanner: ca. 1000 x 3800 x 3000mm Equipment locker: ca. 600 x 600 x 700 mm |

| Mass | Scanner: 300 kg, Equipment locker: 90 kg |

| Max. scanning area | 2500 x 2500 mm |

| Resolution of scanning axis | 0,15 mm (Scanning and index axis) |

| Max. speed of scan axis | 400 mm/s |

| Max. speed of index axis | 125 mm/s |

| Max. mass of test body | 100 kg |

Tab 2: Technical data of the FlatScan 2500 mechanics