AirTech Probes

Of conventional immersion technique probes were used for air-coupled testing, the large acoustic mismatch to air would deliver an amplitude loss of up to 90 dB. Therefore, special probes are required for air-coupled investigations. For ultrasonic inspections, piezoceramic transducers are mainly used, because they are characterized by a high efficiency in the conversion between electrical and acoustic energy. The high acoustic impedance of the piezo material requires a λ/4 adaptation layer to the surrounding air. This adjustment forms a narrowband frequency filter so that "long" ultrasonic pulses are generated in the time domain.

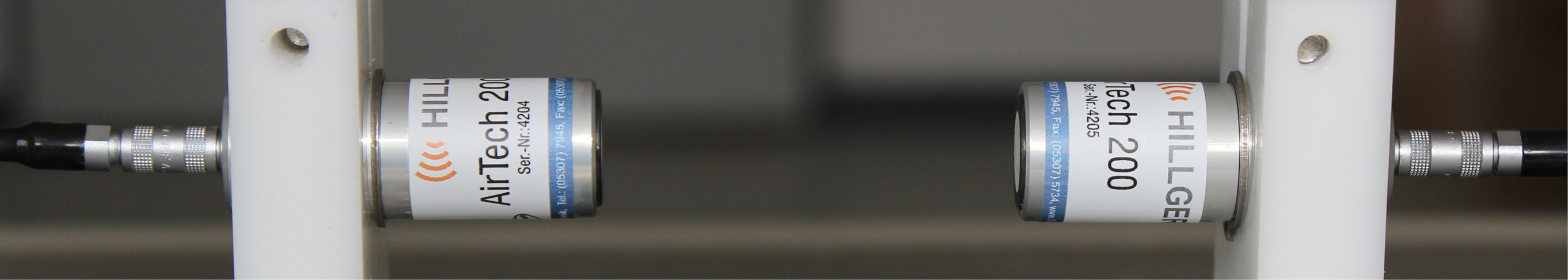

For robust industrial applications, we offer piezoelectric probes in the frequency range from 50 to 300 kHz. These relatively low frequencies compared to conventional ultrasonic inspections are required because of the frequency-dependent attenuation in air. Figure 1 shows our AirTech probes, the technical data are shown in Table 1. Despite of different frequencies, all our probes have the same clamping diameter and can therefore be changed quickly.

The average value of the transducer sensitivity up to 200 kHz is -31 dB. Using a transmitter voltage of 200 Vpp in through-transmission setup without a specimen, the receiver voltage will be about 5.5 Vpp. An additional test component between transducer and receiver transducer typically reduces the receiver voltage of about 80 dB, additionally a defect which has to be detected causes an amplitude drop of 20 dB which leads to a receiver voltage of about 55 µVpp. Therefore, it is important to use transducers with a high sensitivity and ultra-low noise preamplifiers. Otherwise, defect indications may disappear in the electronic noise.

Fig. 1: Overview of our AirTech probes

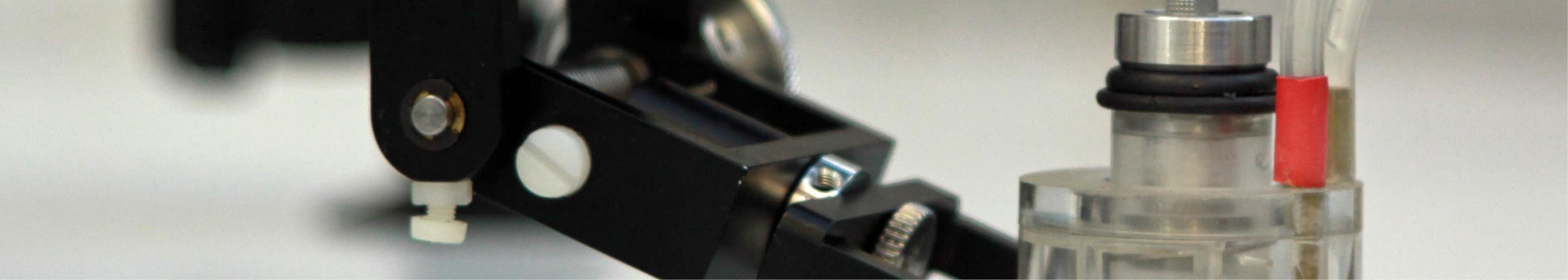

Fig. 2: Application example

| AirTech 50 | AirTech 75 | AirTech 120 | AirTech 200 | AirTech 300 | |

|---|---|---|---|---|---|

| Frequency | 50 kHz | 75 kHz | 125 kHz | 200 kHz | 300 kHz |

| Bandwidth | 5 kHz | 9 kHz | 13 kHz | 21 kHz | 68 kHz |

| Max. Voltage | 1500 Vss | 1000 Vss | 800 Vss | 500 Vss | 400 Vss |

| Active-Ø | 44.5 mm | 30.0 mm | 19.0 mm | 11.0 mm | 7.1 mm |

| Near field lenght | 73 mm | 50 mm | 32 mm | 18 mm | 12 mm |

| Beam-Ø | 13 mm | 8 mm | 5 mm | 3 mm | 2 mm |

| Wavelength in air | 6.8 mm | 4.5 mm | 2.8 mm | 1.7 mm | 1.1 mm |

| Sensitivity | -33 dB | -31 dB | -32 dB | -33 dB | -52 dB |

Tab. 1: Technical data of our AirTech probes

Our AirTech probes are very robust and reliable. All probe types were subjected to an endurance test lasting more than 12 months, each with the highest transmission voltage and 100 Hz pulse repetition frequency. They showed no measurable signs of aging and are therefore ideally suited for industrial applications.

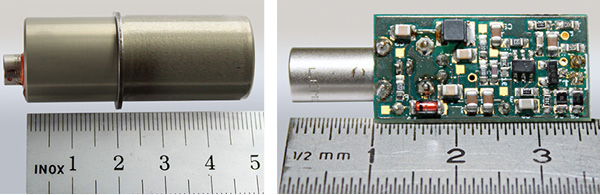

All of our probes are available as AirTech XX-R versions with a built-in ultra-low-noise preamplifier (see Figure 3). The preamplifier provides a gain of 52 dB. Thereby cable lengths of over 100 meters can be used between a probe and the ultrasonic system.

We can also offer focused probes on request.

Fig. 3: AirTech 200-R receiver transducer with built-in ultra-low noise preamplifier.